Phone: +86 18715387320

Email: Kayla@wkxmotor.eu

Introduction :

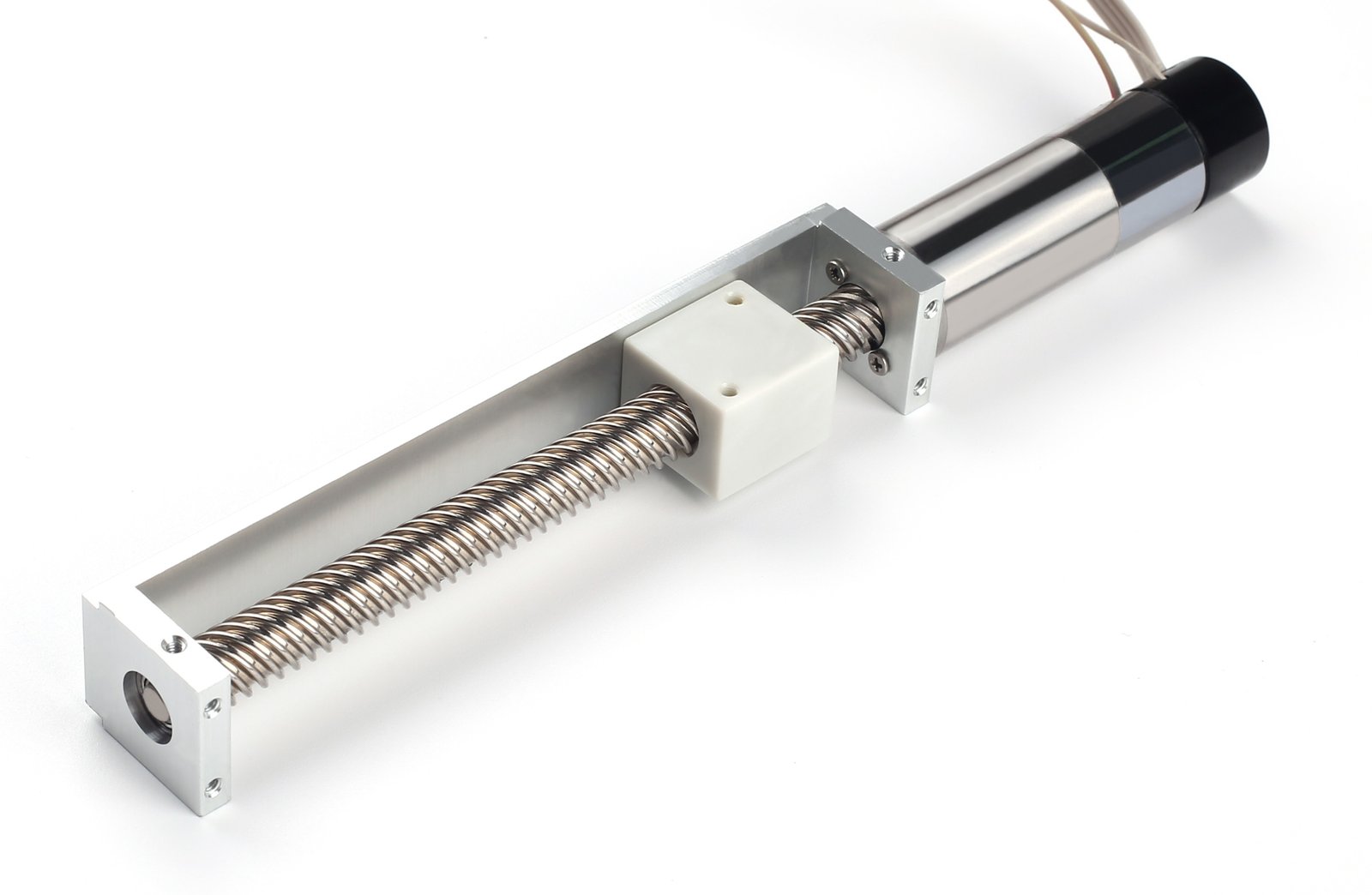

Hollow cup motors extend beyond rotational uses. Paired with lead screws and ball screws, they form high-precision linear positioning systems, enhanced by encoders for speed/position control, precise positioning, and rotor detection. Features Equipped lead/ball screws use metric sizes (M1.2–M3), designed for brushed/brushless motor assembly. Roller technology ensures precision, with stock or custom lengths available. Ideal for applications like precise linear motion, lens zoom/focus, micromirrors, or medical syringes.

Features and Benefits :

🔷 High cost-performance ratio.

🔷 High precision, easy to control.

🔷 Various lead screws available.

🔷 Short delivery times for standard lengths.

🔷 Highly flexible with numerous nut and ball bearing options.

🔷 Customizable lengths upon request.