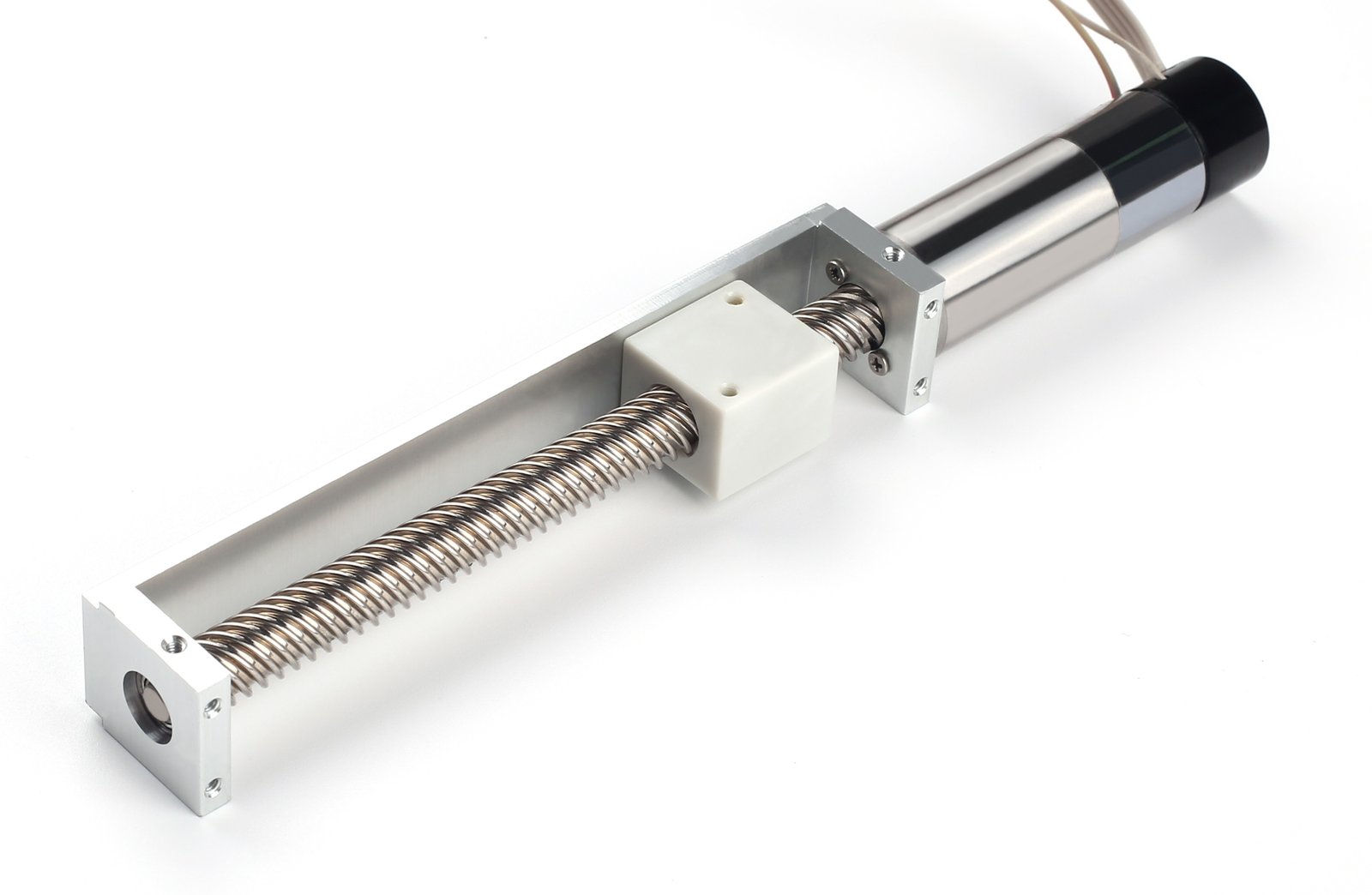

What are the advantages of coreless motors compared to ordinary DC motors?

The structure of the coreless motor breaks through the traditional motor rotor design by adopting a coreless rotor, also known as a coreless cup rotor. This innovative rotor structure completely eliminates power loss caused by eddy currents formed in the iron core. So, what are the advantages of coreless motors compared to ordinary DC motors?

1. High Efficiency

The motor's efficiency stems from the absence of eddy current and hysteresis losses caused by slotted silicon steel sheets in the copper plate coil method. Additionally, low resistance reduces copper losses.

2. High Power Density

Power density is the ratio of output power to weight or volume. The copper plate coil motor is small in size with excellent performance. Compared to traditional coils, the induction coil in the copper plate coil mode is lighter. Without the need for winding or slotted silicon steel sheets, it eliminates eddy current and hysteresis losses. The eddy current loss in the copper plate coil method is minimal and easy to control, improving motor efficiency and ensuring higher output torque and power.

3. Smooth Speed Curve and Low Noise

Without a slotted ferrite core, torque and operating voltage harmonics are reduced. Since there is no AC magnetic field in the motor, there is no AC noise. The only noise comes from rolling bearings, cyclone separators, and vibrations from non-sinusoidal waveforms.

4. No Slot Effect

The copper plate coil is made of slotless silicon steel sheets, eliminating the slot effect caused by the interaction between slots and magnets. The coil is a coreless structure. All steel components either rotate together (as in brushed motors) or remain stationary (as in brushless motors). Slot effects and torque lag are noticeably absent.

5. No Radial Force Between Rotor and Stator

Since there is no stationary ferrite core, there is no axial magnetic field between the rotor and stator. This is particularly important in critical applications, as radial forces between the rotor and stator can cause rotor instability. Reducing radial forces improves rotor stability.

6. No Torque Lag

The slotless silicon steel sheets in the copper plate coil mode eliminate hysteresis losses and slot effects, reducing speed and torque fluctuations.

7. Good Heat Dissipation

The copper plate coil has airflow on both its inner and outer surfaces, providing better heat dissipation than slotted rotor coils. In traditional wire-wound coils embedded in ferrite core slots, there is minimal airflow on the coil surface, leading to poor heat dissipation and higher temperatures. At the same power level, motors using the copper plate coil method have lower temperatures.