Analysis of the Application Scope and Structural Characteristics of WKX Coreless Cup Motors,explained in one article

The core of the WKX motor is its proprietary coreless cup winding, which eliminates cogging effect, minimizes electromagnetic interference, and can achieve an efficiency of up to 90%. It supports an online configuration feature, allowing the motor's shaft, flange, bearings, and electrical interface to be adjusted according to specific application requirements. WKX utilizes automated processes to ensure efficient supply.

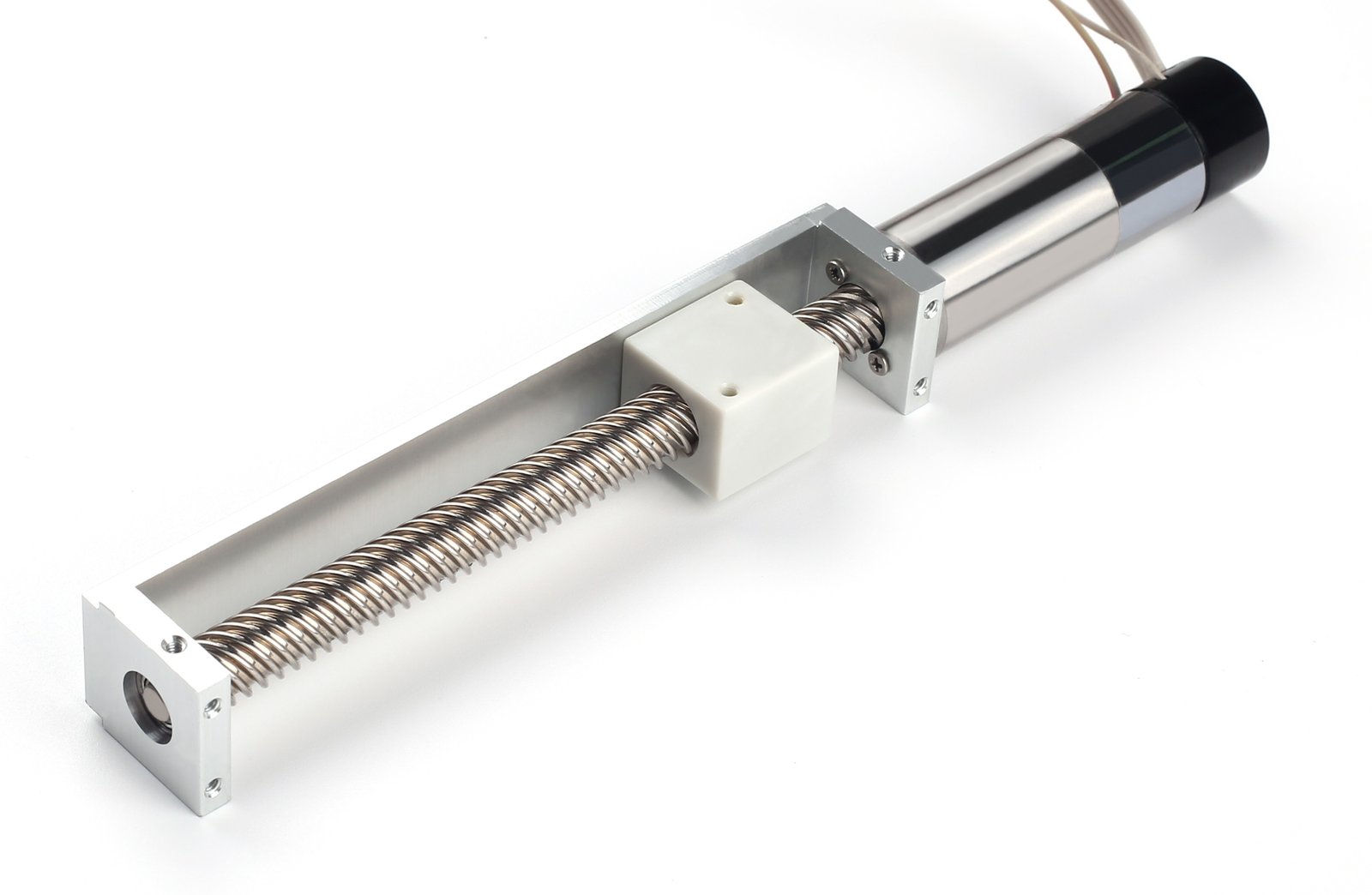

Analysis of the WKX Coreless Cup Motor Structure:

The coreless cup motor is mainly composed of a back cover, terminal block, brush end cap, brushes, commutator, cup-shaped winding (rotor), shaft, washers, sliding bearings, housing, magnet (stator), flange, and a locating ring.

The stator consists of a permanent magnet, housing, and flange. The housing provides a constant magnetic field, which ensures the motor has no iron losses. There are no soft magnetic teeth. The generated torque is uniform, allowing for smooth operation even at low speeds. At higher speeds, the motor reduces vibration and noise. The rotor has windings and a commutator. The windings are connected to the shaft through what are known as commutation plates. The coil moves in the air gap between the magnet and the housing. The commutation system uses a pair of precious metal brushes to reduce brush sparking. This reduced sparking results in fewer electromagnetic emissions.

WKX Coreless Cup Motor Characteristics

1. Driving Characteristics: Operation is highly stable and reliable with minimal speed fluctuation. As a micromotor, its speed fluctuation can be easily controlled to within 2%.

2. Energy-Saving Characteristics: Energy conversion efficiency is very high. Its maximum efficiency is typically above 70%, with some products reaching over 90% (iron-core motors are generally around 70%).

3. Control Characteristics: It offers rapid startup and braking with extremely fast response times. The mechanical time constant is less than 28 milliseconds, with some products achieving less than 10 milliseconds (iron-core motors are typically over 100 milliseconds). The motor's speed can be easily and sensitively adjusted during high-speed operation within the recommended range.

Application of WKX Coreless Cup Motors

The WKX coreless cup motor represents a key development trend in motors across many fields. Its specific applications include:

1. Medical

WKX motors can be widely used in numerous medical applications. In servo systems requiring fast response, coreless cup motors effectively meet technical requirements in high-precision devices such as active implants, insulin pumps, surgical robots, power tools, and bionic hands and feet. They are also capable of performing their functions reliably.

2. Industrial Automation / Robotics

WKX has redefined industrial production, continuously raising the standards for the quality, efficiency, and flexibility of coreless cup motors. Due to their low rotational inertia and easy controllability, coreless cup motors are always ready to meet a wide range of complex application demands.

3. Aerospace

WKX has developed a complete motor solution for civilian airliners, helicopters, spacecraft, and even drones. This includes a variety of individual components and complex technical systems. By leveraging the advantages of coreless cup motors—their light weight, small size, and low energy consumption—they can minimize the weight of aircraft.