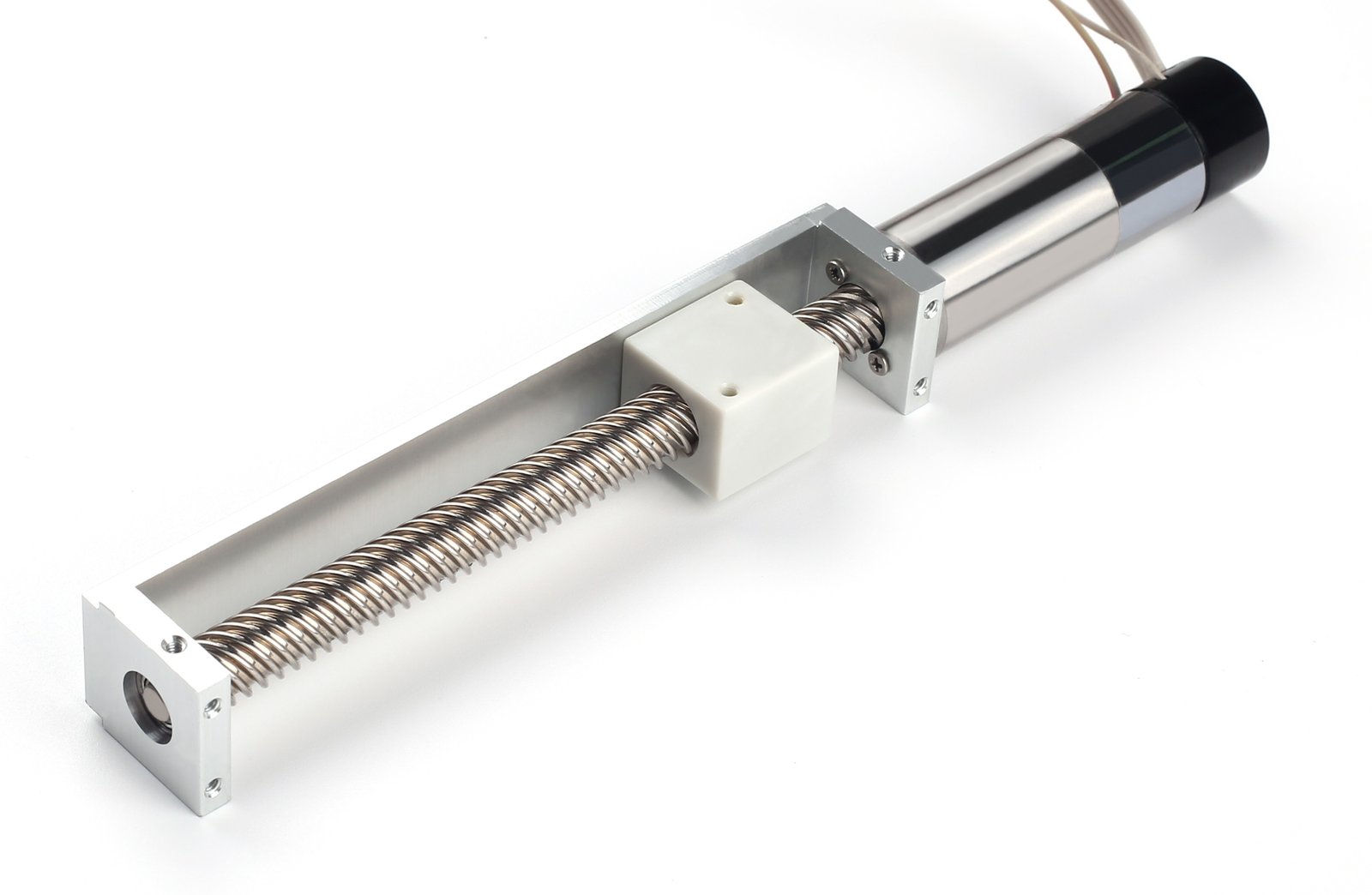

Calculation Method for Transmission Efficiency of Coreless Gear Motors

Transmission efficiency is a key indicator for evaluating the effectiveness of coreless gear motors. Designers need to carefully calculate it during the design process to ensure the equipment meets operational requirements. So, how should we calculate transmission efficiency?

The efficiency of the closed worm gear transmission in a coreless gear motor consists of three components, with the total worm gear efficiency expressed as η = η1 × η2 × η3, where:

- η1: Transmission meshing efficiency. The total worm gear efficiency η primarily depends on the transmission meshing efficiency η1, which accounts for power loss due to relative sliding between tooth surfaces. The meshing efficiency can be approximately calculated based on the efficiency of the screw pair, i.e., where γ is the lead angle at the indexing circle of a standard cylindrical worm, and v is the equivalent friction angle, determined based on the sliding velocity vs.

The transmission efficiency comprises three parts, with the total worm gear efficiency η given by η = η1 × η2 × η3, where:

- η1: Transmission meshing efficiency. The total worm gear efficiency η mainly depends on the transmission meshing efficiency η1, which considers power loss due to relative sliding between tooth surfaces. The meshing efficiency can be approximately calculated based on the efficiency of the screw pair.

Thus, the total worm gear efficiency η primarily depends on the transmission meshing efficiency η1, which accounts for power loss due to relative sliding between tooth surfaces. The meshing efficiency can be approximately calculated based on the efficiency of the screw pair, where:

- η2: Efficiency related to oil churning and splashing losses.

- η3: Bearing efficiency.

Generally, when calculating the transmission efficiency of a coreless motor, these three factors must be comprehensively considered and adjusted in combination to achieve a reasonable cost-performance ratio for the equipment.