What are the common types of micro DC motors used in intelligent robots?

What are the common micro DC motors used in intelligent robots? Intelligent robots can perform various actions such as walking, jumping, and rotating. These actions are realized by the rotational drive of micro DC motors. Different parts and functions of an intelligent robot use different types of micro motors. WKX MOTOR will give you a brief introduction to the micro DC motors commonly used in intelligent robots.

A Micro DC Brushed Motor is a widely used type of micro motor, also common in products like electric toys, smart door locks, and electric shavers. It can rotate at high speeds simply by being powered by direct current. However, the torque of a micro DC motor is often too small. Since robots typically do not require excessively high rotational speed, they are mostly used with a gear reducer. This not only reduces the speed but also increases the torque, giving the micro DC motor a broader range of applications. It also has the advantages of easy and simple speed control, large starting torque, and stable operation.

Another type is the Servo Motor, which is also very common in intelligent robots. A servo motor is not a standalone motor; it is composed of a micro DC motor, gears, a circuit board, a position detector, and a casing. Its working principle involves a signal sent by the receiver. This signal is sent via an IC on the circuit board to the servo motor to determine the direction of rotation. The micro DC motor then rotates to drive the gears, transmitting power to the output arm. Simultaneously, a position detector sends back a signal to determine whether the target position has been reached. The position detector is essentially a variable resistor. As the servo motor turns, the resistance value changes, and by detecting the resistance value, the angle of rotation can be known.

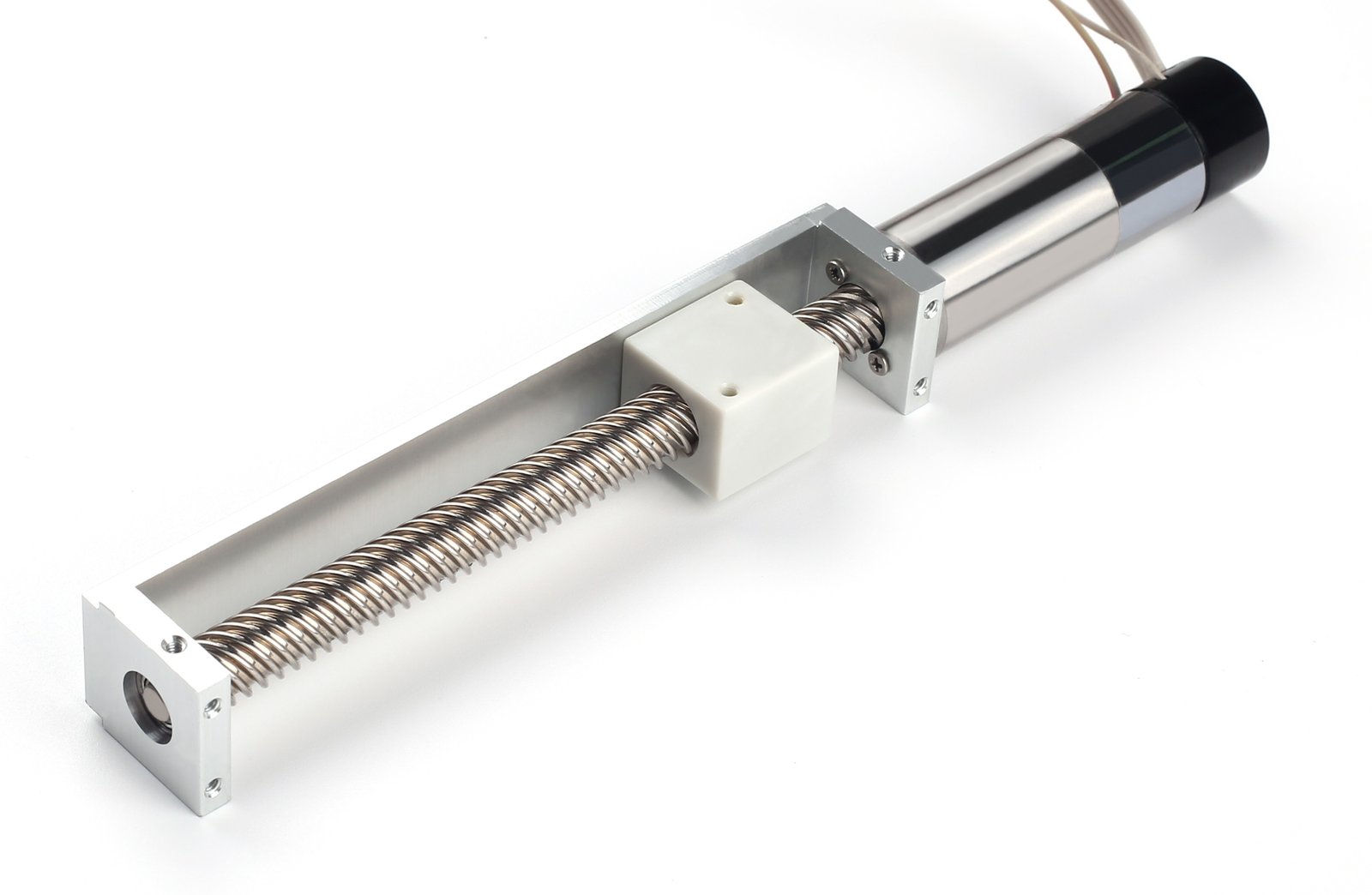

The Stepper Motor in intelligent robots is primarily an open-loop control element that converts electrical pulse signals into angular or linear displacement. In non-overload conditions, the motor's speed and stopping position are determined solely by the frequency and number of pulse signals, and are not affected by load changes. When the stepper driver receives a pulse signal, it drives the stepper motor to rotate by a fixed angle in the set direction, known as the step angle. Its rotation is carried out incrementally by this fixed angle. By controlling the number of pulses, the displacement can be controlled to achieve the goal of precise positioning; simultaneously, by controlling the pulse frequency, the motor's rotational speed and acceleration can be controlled to achieve the goal of speed regulation.

These are a few of the common types of micro DC motors used in intelligent robots. Micro DC motors are also divided into brushed motors and brushless motors. Brushed motors are easy to control and low-cost. Brushless motors have complex control systems and higher costs, but they can be customized according to different requirements.