How to reduce coreless DC motor noise?

How to eliminate the noise of a coreless DC motor?

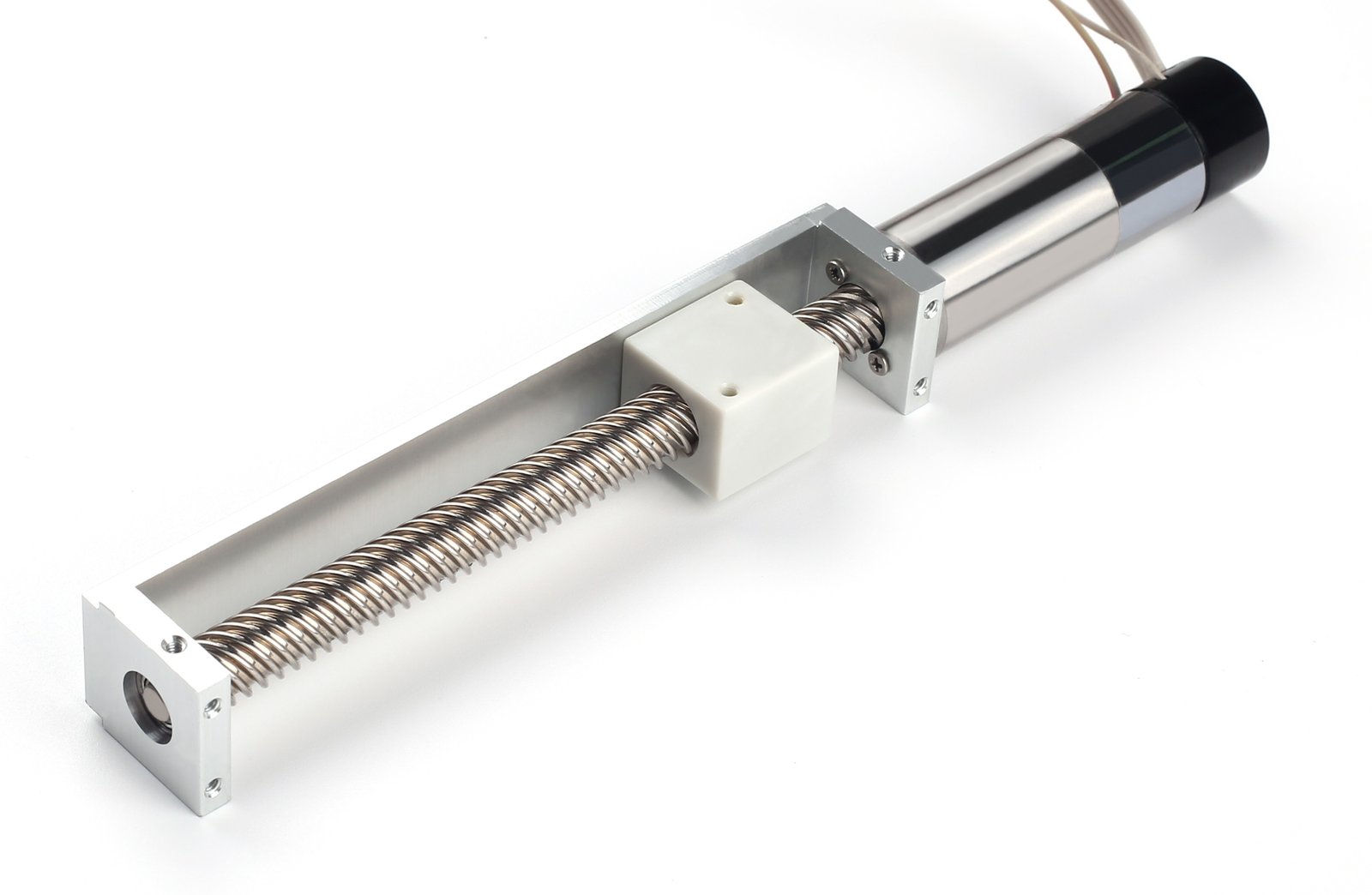

A coreless DC motor is connected to a power source via a commutator and brushes. When current flows through the coil, a magnetic field generates a force that causes the DC motor to rotate, producing torque. The speed of a brushed DC motor is changed by varying the operating voltage or the magnetic field strength. Brushed motors tend to produce a lot of noise (both acoustic and electrical). If this noise is not isolated or shielded, the electrical noise can interfere with the motor circuit, leading to unstable motor operation. The electrical noise generated by DC motors can be divided into two categories: Electromagnetic Interference (EMI) and electrical noise. Electromagnetic radiation is difficult to diagnose, and once a problem is detected, it is hard to distinguish it from other noise sources. Radio Frequency Interference (RFI) or electromagnetic radiation interference is caused by electromagnetic induction or electromagnetic radiation emitted from external sources. Electrical noise can affect the effectiveness of the circuit, and this type of noise can lead to the simple degradation of the machinery.

When a coreless DC motor operates, sparks may occasionally occur between the brushes and the commutator. Sparks are one cause of electrical noise, especially during motor startup when a relatively high current flows into the windings. Higher current generally leads to higher noise. Similar noise also occurs when the brushes remain unstable on the commutator surface and the motor's input is far higher than expected. Other factors, including the insulation formed on the commutator surface, may also lead to current instability.

Electromagnetic signals generated by coreless motors can also couple into the circuit, forming what is known as common-mode interference. This type of interference cannot be eliminated by shielding but can be effectively reduced by a simple LC low-pass filter. To further reduce electrical noise, filtering is required at the power supply. This is usually done by adding a large capacitor (e.g., 1000μF and above) across the power terminals to lower the effective resistance of the power supply and thus improve the transient response. A filter-smoother circuit is often used to manage overcurrent, overvoltage, and LC filtering.

Another source of noise is the power supply itself. Since the power supply's internal resistance is not zero, the non-constant motor current translates into voltage ripple on the power supply terminals during each rotation cycle. Coreless DC motors generate noise during high-speed operation. To reduce electromagnetic interference (EMI), the motor should be placed as far away as possible from sensitive circuitry. The motor's metal casing usually provides adequate shielding to reduce airborne EMI, but an additional metal enclosure should provide better EMI reduction capability.

Electromagnetic signals generated by coreless motors can also couple into the circuit, forming what is known as common-mode interference, which cannot be eliminated by shielding but can be effectively reduced by a simple LC low-pass filter. To further reduce electrical noise, filtering must be done at the power supply. This is typically achieved by adding a large capacitor (such as 1000μF and above) at the power end to reduce the effective resistance of the power supply, thereby improving the transient response.

Capacitors and inductors generally appear symmetrically in the circuit to ensure circuit balance, forming an LC low-pass filter to suppress conducted noise generated by the carbon brushes. The capacitor mainly suppresses the voltage spikes caused by the random disconnection of the carbon brushes and also provides good filtering function. Capacitors are generally installed connected to the ground wire. The inductor primarily prevents sudden current changes in the gap between the carbon brushes and the commutator copper segments. Grounding can enhance the design performance and filtering effect of the LC filter. Two inductors and two capacitors form a symmetrical LC filtering function. The capacitors mainly eliminate the voltage spikes generated by the carbon brushes, while a PTC (Positive Temperature Coefficient) device is used to eliminate the impact of excessive temperature and current surges on the motor circuit.

To reduce the level of electromagnetic interference (EMI), the coreless motor should be placed as far away as possible from sensitive circuitry to minimize interference, and an additional metal enclosure should also be provided. To suppress EMI in the case of common-mode interference, a simple LC low-pass filter is built-in. Other electrical noise can also be eliminated by connecting the motor with a simple speed controller, and a higher-order LC filter can further improve noise filtering performance.