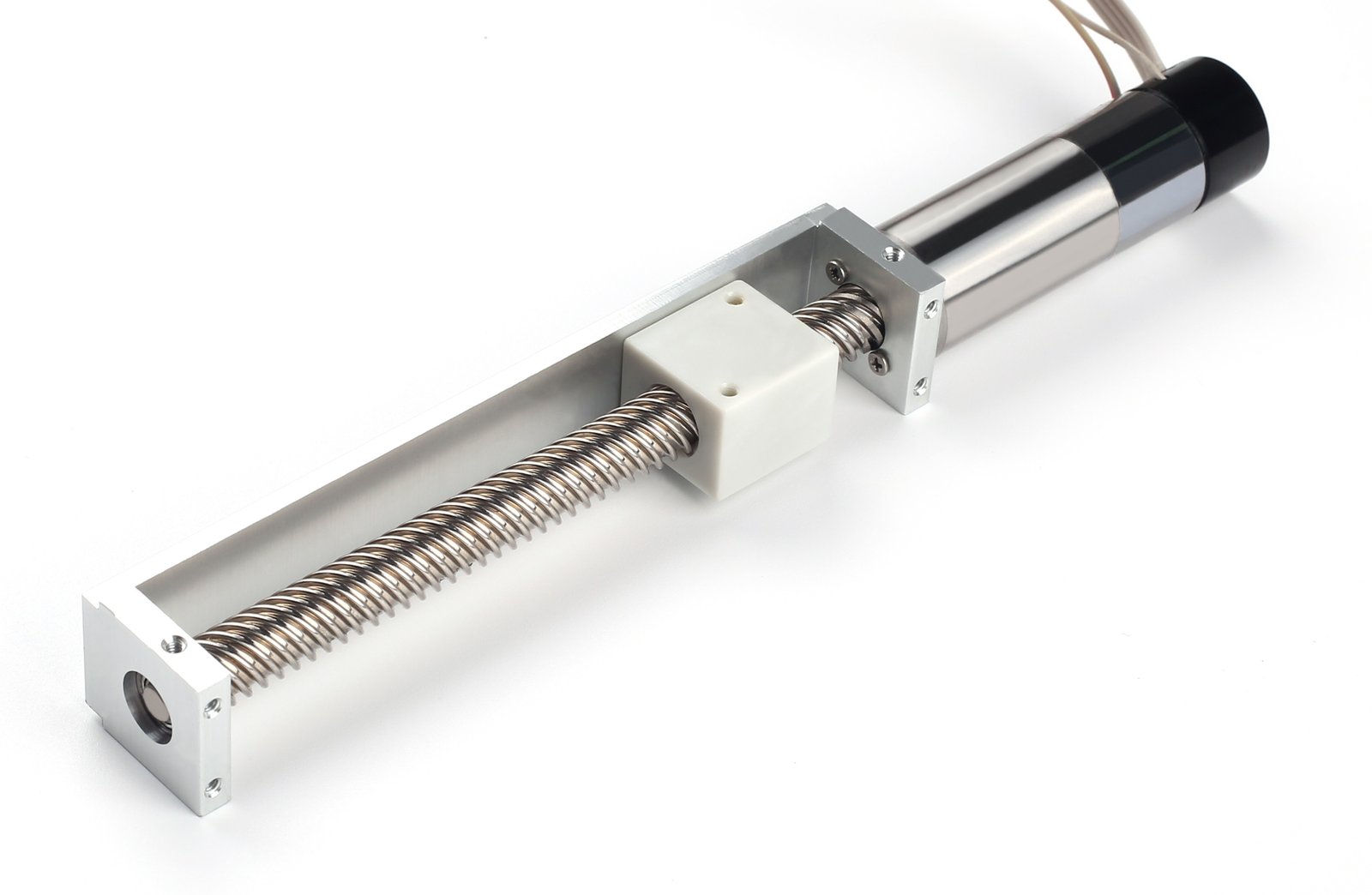

What details should be noted when installing a coreless motor?

What details should be noted when installing a coreless motor? No matter what task we undertake, there are always specific details that require special attention. So, what details should be considered when installing a coreless motor? Let’s take a look at the information compiled by WKX MOTOR:

Details to Note When Installing a Coreless Motor:

When operating at its nominal rated voltage, a coreless motor exhibits excellent overall performance. It is recommended to design the circuit so that the operating voltage is as close as possible to the rated voltage. The control module supplying power to the coreless motor should have a low output impedance to prevent significant voltage drops under load, which could affect the vibration performance.

When designing the positioning slot for a motor with a mounting bracket, ensure that the gap between the motor and the device housing (e.g., phone shell) is not too large, as this may cause additional vibrations (mechanical noise). Using a rubber sleeve for fixation can effectively reduce mechanical noise, but note that the positioning slot on the housing and the rubber sleeve should use an interference fit. Otherwise, it may affect the motor’s vibration output and reduce the vibration sensation.

During transportation or use, avoid placing the motor near strong magnetic fields, as this could deform the motor’s magnetic steel surface and impact performance. Pay attention to the welding temperature and duration. It is recommended to use 320°C for 1–2 seconds. Excessive temperature or prolonged welding time may damage the insulation of the lead wires. When removing the coreless motor from its packaging or during welding, avoid forcefully pulling the lead wires or repeatedly bending them at large angles, as this could damage the wires.

This concludes the introduction to the installation details of coreless gear motors. Please keep these points in mind when installing coreless motors to ensure proper operation.