Which has greater force: a micro brushless DC motor or a micro brushed DC motor?

Micro DC motors can provide various types of power, such as lifting, vibration, or oscillation. Depending on the primary application area, the type of micro DC motor used varies, and their key parameters also differ. These motors can be divided into micro brushed DC motors and micro brushless DC motors. So, which of these two types of micro DC motors has greater force? Torque is a particularly critical parameter for comparison in micro DC motors, as it determines the ability to drive a load—the larger the load, the greater the force required. Under the same power rating, the load-bearing capacity of a micro brushed DC motor is lower than that of a brushless motor. From the basic operating principles of micro motors, micro brushed DC motors and micro brushless DC motors are fundamentally similar. The key difference lies in the fact that brushed motors use mechanical commutation, relying on continuous friction between carbon brushes and the commutator to adjust the current direction. In contrast, brushless motors use electronic commutation devices, eliminating the need for brushes and a commutator.

Advantages and Disadvantages of Micro Brushless DC Motors

1) Advantages:

Lightweight and compact in size with high torque.

Due to the absence of carbon brushes and commutators, they have a longer lifespan, limited only by bearing wear.

High efficiency with no brush friction loss or excitation loss.

Capable of stepless speed regulation with a wide speed control range.

2) Disadvantages:

The use of electronic commutation requires Hall sensors to replace brushes and commutators, and most designs rely on neodymium-iron-boron permanent magnet materials, making speed control less precise compared to micro brushed motors.

Control systems are more complex, and costs are typically 1–3 times higher than those of brushed DC motors.

Advantages and Disadvantages of Micro Brushed DC Motors

1) Advantages:

Low cost and affordable.

Smooth operation with high starting torque.

Simple and convenient speed regulation.

2) Disadvantages:

Limited lifespan, generally less than 1,000 hours due to brush and commutator wear.

Comparison and Application

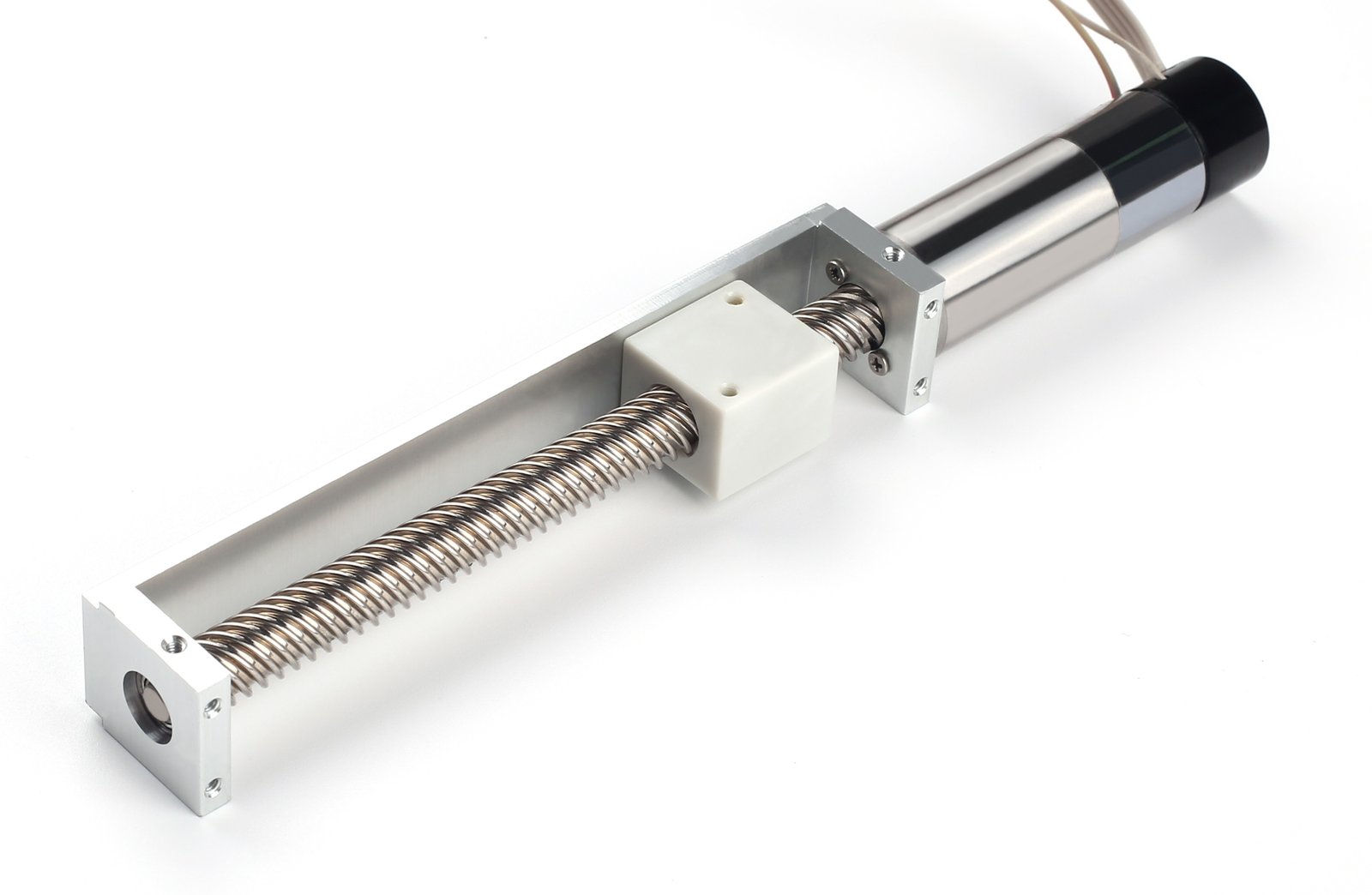

Both micro brushed and brushless DC motors can increase torque by incorporating gear reduction systems. Under the same parameters, micro brushless DC motors generally provide greater force but come with higher costs. If a micro brushed DC motor can meet the functional requirements, most users opt for it due to its lower cost.

About WKX Motor

WKX Motor is a comprehensive enterprise integrating research, development, production, and sales of micro motors. It specializes in manufacturing coreless brushed motors, coreless brushless motors, and supporting gear reducers.