In Vitro Cultivation: Rapid Diagnosis, Automated, and Error-Free

Countless samples are tested in laboratories every day. Automation offers clear advantages in this field, enabling faster processing, higher throughput, fewer errors, and lower personnel costs. To ensure smooth operation of drive systems, high dynamic performance and precision are critical. WKXMOTOR introduces us to the demands and developments in this niche market.

In which industries can laboratory automation be applied? Which industry finds laboratory automation effective?

Automation processes are found in all laboratory fields, such as technology, food science, pharmaceuticals, and chemistry. The medical industry is one of the fastest-growing early adopters globally. For many years, automated solutions have become indispensable in the analysis of medical samples (e.g., blood, urine, and tissue) in areas like in vitro diagnostics (IVD). In the development of new drugs by pharmaceutical companies, laboratory testing procedures are also automated.

What exactly is laboratory automation?

It depends on the degree of automation in the laboratory. The scope ranges from using standalone equipment to perform individual processes to conducting complete sample analysis with complex systems. The latter is used for handling large volumes of samples tested through standardized experimental designs. This is particularly necessary when flexibility is not required. For example, it applies to in vitro diagnostics (IVD) in hospital clinical chemistry laboratories and large medical analysis laboratories.

In these fields, which processes are automated?

In these laboratories, most analytical procedures are performed automatically. Initially, blood samples are prepared in color-coded test tubes. A scanner records the type of analysis required for each tube, allowing an automated arm to accurately retrieve it. Some samples undergo centrifugation to separate various blood components. The samples are then placed in a dedicated transport device and sent to an actual analysis station, such as a cart driven by belts or rollers.

What happens at the analysis station?

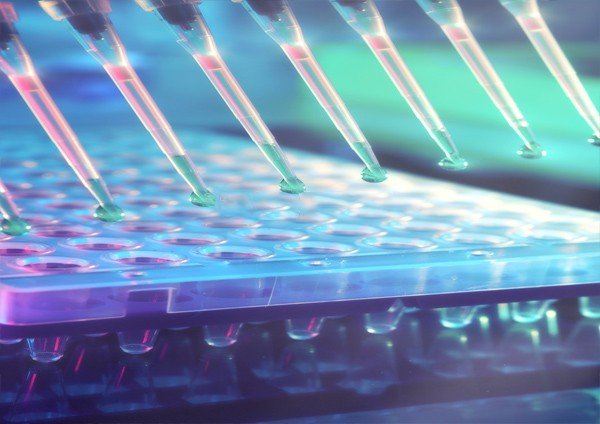

First, the barcode on the sample is read by a camera. Then, the test tube stopper is moved, and a few samples are extracted. The test tube is resealed and stored for future checks. The sample is transferred to a reaction container, such as a test plate or petri dish, for actual analysis. In subsequent testing, drive technology is primarily used for processes like stirring, mixing, liquid handling, and liquid transfer.

What requirements must motors meet?

The entire process involves a variety of operations, each with different requirements for drive technology. Belt conveyors, for instance, are large and require high motor power, while smaller components need to be lightweight. With our extensive range of products, we can meet the full spectrum of these demands. Additionally, we offer highly effective solutions that fulfill most requirements.

Can you give us a few examples?

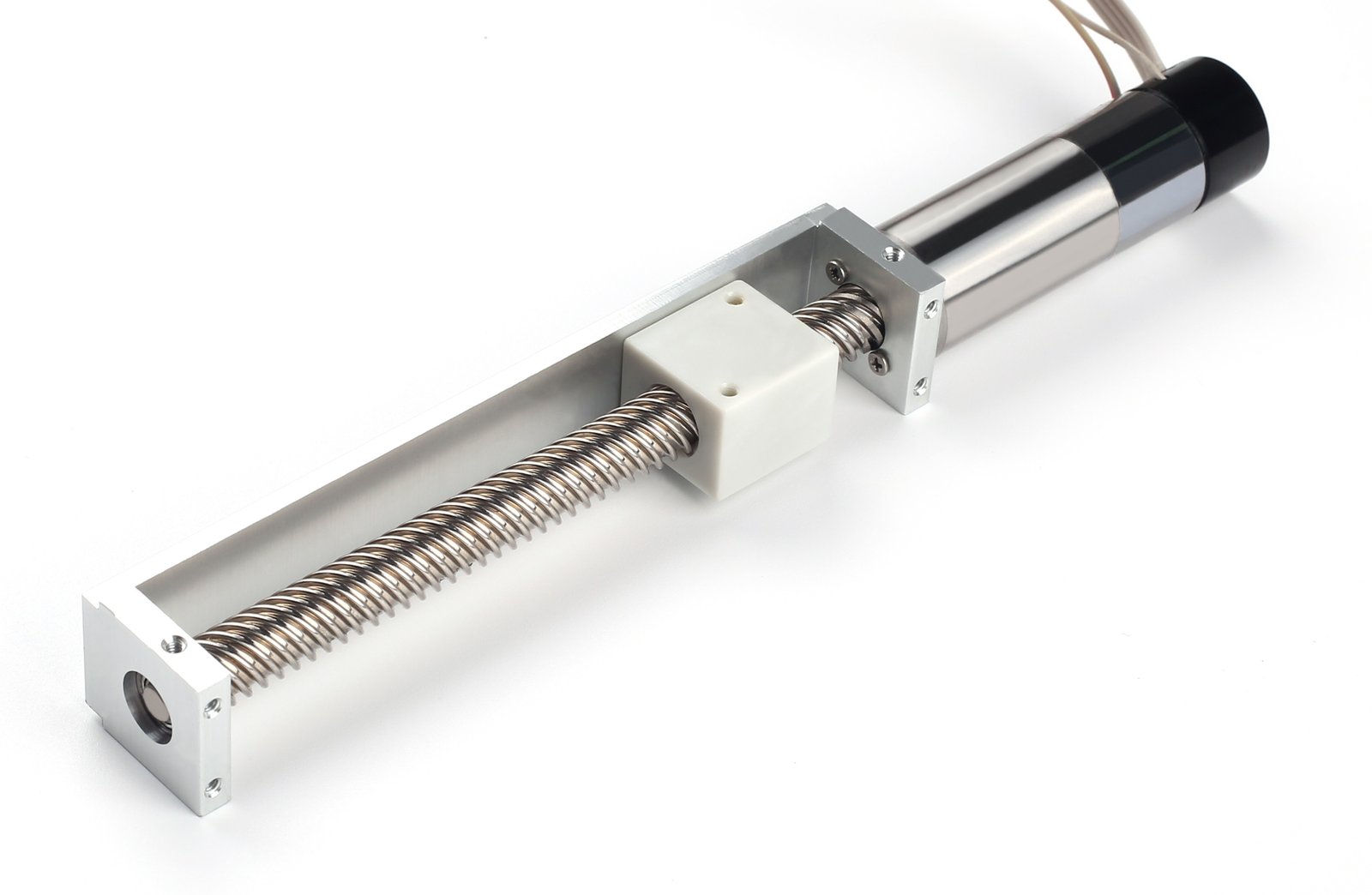

In many applications, systems require excellent dynamic performance to handle repetitive on/off movements. When doing so, both speed and highly precise positioning are essential. Size and weight are also critical factors: in moving components, many drive systems are responsible for the vertical motion of tube arms and pipettes. Therefore, they should be very lightweight and compact.

What are the advantages of WKX motors?

The RE1625 and RE2228 series DC micro-motors are particularly well-suited for these applications. With a coreless design, they are lighter and smaller than other models, offering superior dynamic performance. They are typically used in combination with encoders, with the total device length being only 2mm. This compact design enables high performance.

What are other reasons for choosing WKX products?

For our customers, ensuring the use of high-quality components that are more reliable and have a longer service life is crucial. Ninety percent of their profits come from selling reagents used with sample analyzers. Therefore, the expected lifespan directly impacts the continuity of reagent sales. Additionally, in vitro diagnostic (IVD) equipment requires a rigorous certification process before operation begins. Replacing existing equipment must be avoided, as the certification process would need to be repeated. Having interchangeable components is also important. If prolonged use requires changes to WKX’s system components, customers can rest assured. Even after several years, these components remain available for purchase.