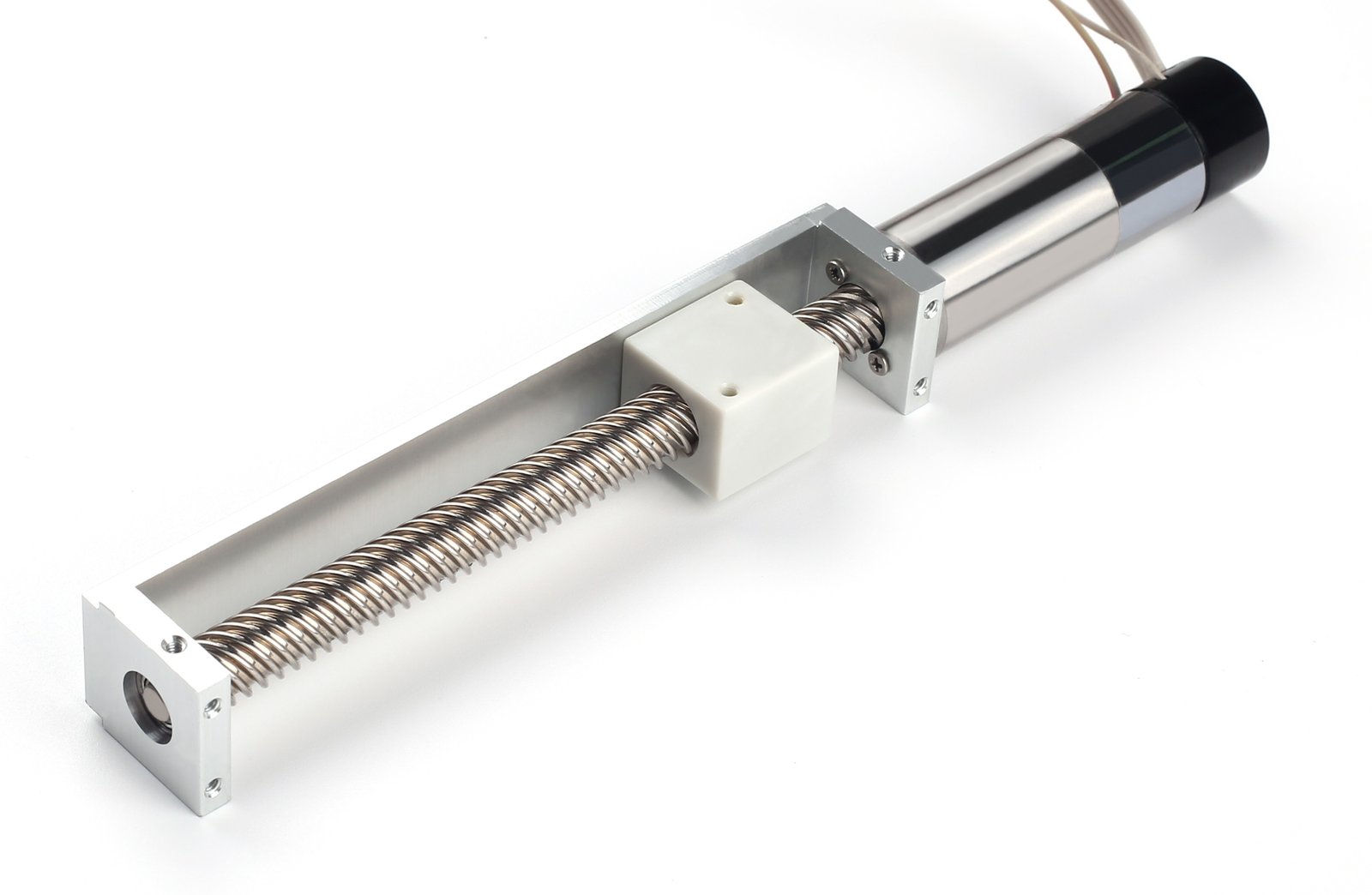

Coreless DC Motor-Technical Information

WKX MOTOR Winding

The main advantages of this technology include:

🔷 Achieving smooth positioning and drive speed regulation through toothless torque, with an overall efficiency higher than that of other types of DC motors.

🔷 Delivering extremely high torque and power relative to the motor's own volume and weight.

🔷 Maintaining an absolute linear relationship between load and speed, current and torque, as well as voltage and speed.

🔷 Extremely low moment of inertia, enabling excellent dynamic characteristics for startup and shutdown.

🔷 Minimal torque ripple and electromagnetic interference.

DC Motor Types

WKX MOTOR DC motors are available with two different commutation systems: precision alloy commutation and carbon brush commutation.

🔷 The term "precision alloy commutation" refers to a system where the materials used for the brushes and commutator contain high-performance precious metal alloys. This type of commutation system is mainly used in applications requiring extremely small size, very low contact resistance, and precise commutation signals. It is particularly suitable for low-current applications, such as battery-powered devices.

🔷 Generally, motors with precision alloy commutation can exhibit excellent overall performance when operating continuously under the load corresponding to their maximum nominal efficiency.

🔷 The term "carbon brush commutation" refers to a system where the brush material is paired with a copper alloy commutator. This type of commutation system is highly robust and more suitable for dynamic high-power applications involving rapid startup/shutdown or intermittent periodic overload conditions.

Magnets

WKX DC motors are designed to use a variety of different magnet types to achieve the specific performance of the designated motor type. These materials include:

🔷 Alnico magnets

🔷 High-performance rare-earth magnets (e.g., samarium-cobalt permanent magnets and neodymium-iron-boron permanent magnets)

Operating Life

The service life of WKX DC motors mainly depends on the operating working point and ambient conditions during operation. Therefore, the total operating hours can vary significantly:

🔷 From several hundred hours under extreme conditions to over 25,000 hours under optimal conditions.

🔷 Under typical load conditions, the operating life of a WKX DC motor is approximately between 1,000 and 5,000 hours.

🔷 Generally speaking, the service life of a WKX DC motor is limited by the electrical wear and mechanical wear of the commutator and brushes. Electrical wear (sparking) mainly depends on the electrical load and motor speed.

🔷 As the electrical load and motor speed increase, the typical service life of the motor tends to decrease. Motors with precision alloy commutators are more significantly affected by electrical wear, and the nominal voltage of the winding also has a great impact. Therefore, when necessary, WKX DC motors are equipped with built-in spark suppression to reduce the negative impact of sparking on the operating life.

🔷 The mechanical wear of the commutation system depends on the motor speed and increases with the increase of speed. Generally, for applications with speed and load higher than the specified values, motors with carbon brush commutators have a longer service life.

🔷 It is equally important not to exceed the load characteristics of the motor bearings during continuous operation as specified in the data sheet, as this situation can also limit the achievable service life of the motor.

🔷 Other factors affecting motor life include external conditions such as excessive humidity and temperature, excessive impact and vibration, as well as incorrect or suboptimal motor installation configuration in the application.

🔷 Meanwhile, it is important to note that the method of driving and controlling the motor greatly affects the motor's operating life. For example, when using PWM (Pulse Width Modulation) signals to control the motor, WKX MOTOR recommends a frequency of no less than 20 kHz.

Modifications

WKX MOTOR is committed to meeting customer application requirements by configuring various standard products. The available modifications for WKX DC motors include:

🔷 Multiple other nominal voltage types

🔷 Motor leads (PTFE and PVC) and connectors

🔷 Configurable motor shaft length and secondary shaft end

🔷 Customizable shaft dimensions and pinion configurations (e.g., flat steel, gears, pulleys, and eccentric wheels)

🔷 Modified versions for operation at extremely high or low temperatures

🔷 Modified versions for operation under vacuum conditions (with an extreme value of 10⁻⁵ Pa)

🔷 Modified versions for high-speed and/or high-load applications

🔷 Motor modifications with higher precision than standard electrical or mechanical tolerances